Project Introduction

Location: Shanghang County, China

Project Name: Zijin Mining ORing Solution

Products Deployed: IGS-3044GC,RGS-7244GP

Project Requirement

- Create an Ethernet network connecting each subsystem to the ground system

- High network reliability with redundancy and management functions.

- Gigabit speed

- Resistance to harsh environments

- Real-time alert and event management

Solution

Located in Shanghang County, covering an area of 30 km2, the Zijinshan Gold & Copper Mine is Zijin Mining’s core business. Discovered in the 1980s, Zijinshan Gold & Copper Mine is one of the most important mines in China. As of 2015, the gold resource reserves reached 317.5 tons and the copper resource reserves reached 208.6 tons. The prospective resource reserves exceed five million tons. To ensure mining safety, the Chinese government has required all mines in China to be equipped with six safety systems, including the monitoring system, the positioning system, the water supply system, the compressed air self-rescue system, the communications system, and the emergency system. In alignment with the government’s policy, Zijin Mining started to install these systems in its Zijinshan Gold & Copper Mine in 2010 with installation completed in 2015.

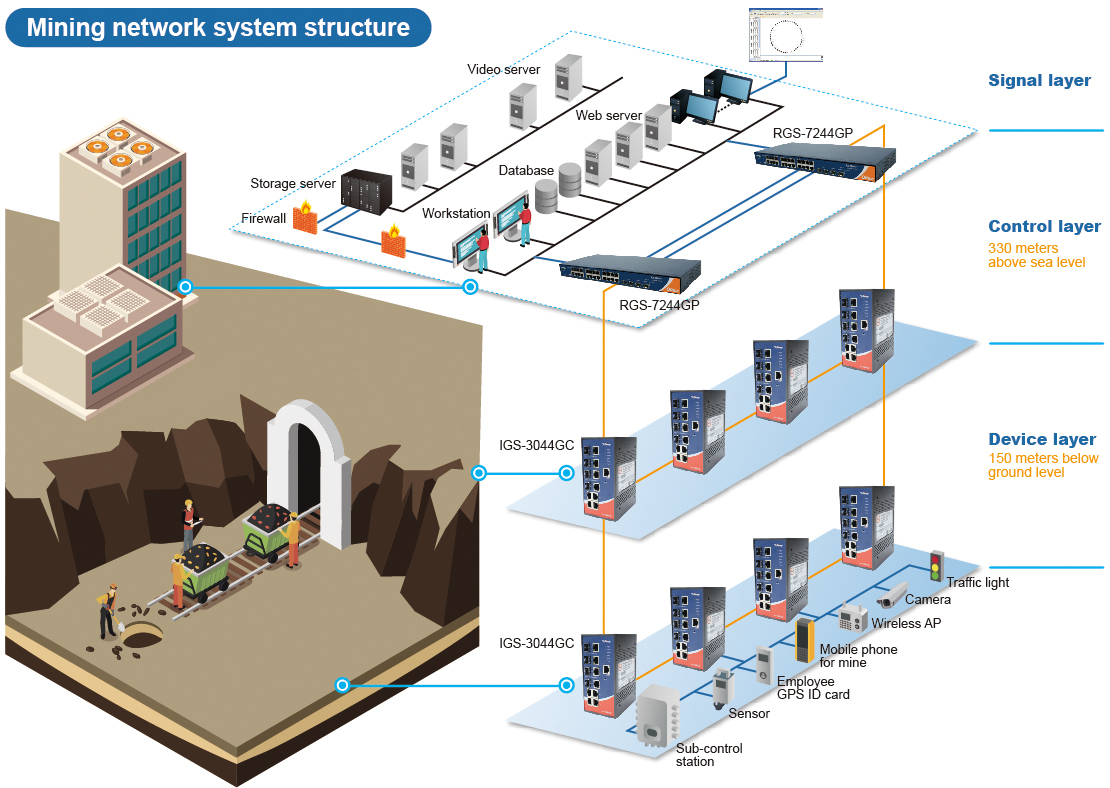

This mine contains six mining levels as well as several slopes and portals. The six mining levels are located at 330 meters, 354 meters, -100 meters, -50 meters, -150 meters, and 245 meters. The customer formed a fiber backbone network in ring topology between the safety and production control center, portals, and shafts. Fiber sub-networks were also formed at each section to connect the shafts and slops. All of these networks were built using ORing’s industrial Ethernet switches including two RGS-7244GP and 120 IGS‐3044GC which are managed via ORing’s Open-Vision software. ORing’s solutions fully address the customers’ requirements as the switches feature industrial-grade design and support ORing’s proprietary network redundancy technology O-Ring and O-Chain. Therefore, the network can recover automatically in 30ms, even if the network reaches the maximum number of nodes.

Underground network: data from underground equipment such as the sub-monitoring sites, sensors, positioning devices, mobile phones, wireless base stations, cameras, and traffic lights is transmitted to the control center through ORing’s IGS-3044GC. The underground network allows for security surveillance and automated control. Despite the harsh working environment, the IGS-3044GC is able to provide reliable data communications due to its Gigabit speed and compact size.

Control center: the two RGS-7244GP rack-mount industrial Ethernet switches at the control center form a resilient network to receive data from underground devices. With 28 Gigabit ports including 24 copper and 4 fiber ports, the switch can support a huge amount of data from the large number of underground devices. Same as the IGS-3044GC in the remote site, the RGS-7244GP supports O-Ring network redundancy technology which allows for network recovery in less than 30ms. The two RGS-7244GP switches also ensure uninterrupted operation when one of them fails.

Management software: The customer has installed ORing’s Open-Vision to help staff manage the network and all network devices with ease. With Open Vision, the staff can monitor, manage, and configure maximum 500 devices on a single control panel. The network topology is created automatically and the status of each node is visualized on the screen. In addition, the staff can identify problems from the activity log and perform troubleshooting immediately.

System Structure

Why ORing

•Comprehensive networking solutions, including access switches, aggregation switches, and management software

•Fast self-healing with O-Ring and O-Chain network redundancy technology

•Gigabit speed

•A wide temperature range and five-year warranty