Project Introduction

Location: China

Project Name: ORing Connects Tesla's Car Plant to Internet

Products Deployed: IES-150B

Project Requirement

- Build an industrial communications network to facilitate data transmission

- Ensure network stability and reliability to prevent data loss

- Small-sized and DIN-rail mountable switches

Solution

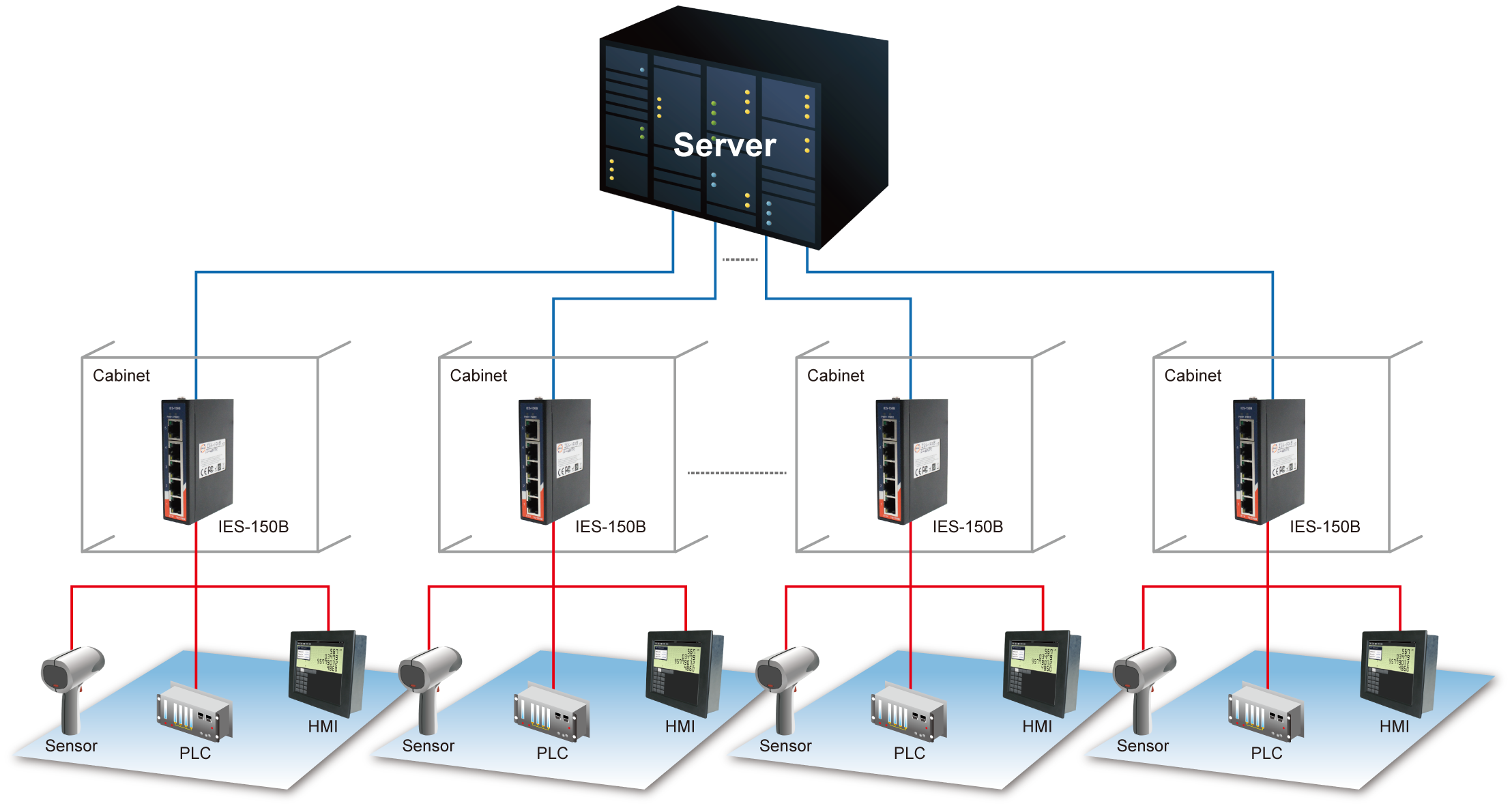

The car part inspection system consists of a large number of sensors, PLCs, and HMIs to monitor, manage, and collect the inspection data of car parts. Industrial switches are needed to connect the sensors, PLCs, and HMIs to the network which then transmits the data to the control center. Due to space limit in the cabinet, the industrial switches must be compact with a high cost-performance ratio.

Tesla has installed ORing's IES-150B unmanaged industrial Ethernet switch to connect the sensors, PLCs, and HMIs efficiently. Equipped with five Fast Ethernet ports, the IES-150B provides several industrial features such as IP30 protection, high EMI immunity, a wide operating temperature range from -40 ~ 70℃, DIN-rail installation, a MTBF of 2.6 million hours, and a five-year warranty.

With a size of 26.1mm x 70mm x 95mm, the IES-150B boasts the smallest form factor among the other mainstream industrial Ethernet switches, dramatically reducing space requirements.

ORing's abundant hands-on experience in applications and on-site services has also contributed to the project significantly.

System Structure

Why Oring

- Compact size and easy installation as the IES-150B is the smallest industrial Ethernet switches in the world

- Steady performance with no packet loss and latency to provide a stable industrial network.

- Enriched hands-on project experience in industrial automation

- Made-in-Taiwan products which can be shipped based on customer's requirements